What is the Reverse Engineering?

The concept of reverse engineering has different meanings according to occupational groups. In cases where the design information of a manufactured product is not available, the design information is recovered for the purpose of reproducing or improving the product.

What are Reverse Engineering Stages in Manufacturing?

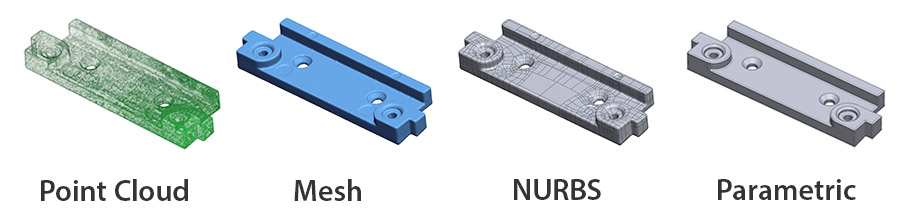

1. The physical model is obtained in digital environment by using three-dimensional digitization or scanning tools.

2. A number of correction operations are applied on the obtained model.

3. Corrected point cloud and section curves Surfaces are obtained by using reverse engineering modules in CAD software.

4. The final CAD data is obtained after the necessary final corrections are made on the obtained surface models.

Advantages and Uses