What is 5-Axis Machining?

Cnc machine that can move 5 different axes at the same time. The ability to move 5 axes together allows the machining of complex parts. Besides the X, Y, Z linear axes, the A and B axes can also rotate.

Why 5-Axis Essential ?The combination of 5 axes is especially necessary in the manufacture of complex parts used in the aerospace and defense sectors. It allows you to produce the part completely with a single setting, thus eliminating the time loss caused by multiple setting times.

What are the 5-Axis Benefits?

Increase in production

More precise parts production without re-adjustment

High cutting speed and feedrate

Low tool vibrations

Complex machining with one setting

High surface qualities

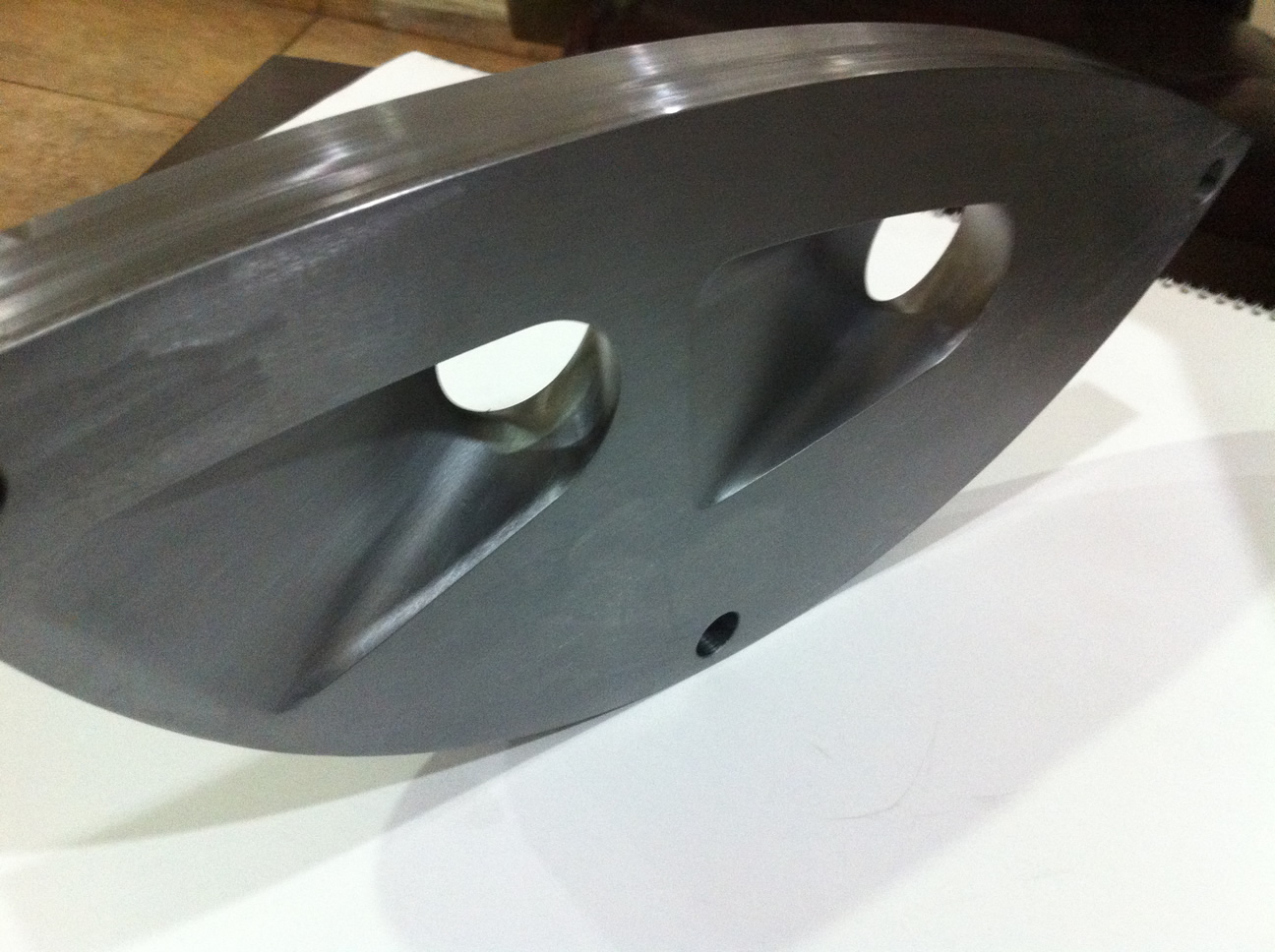

Centrifugal compressors, which are generally preferred in unmanned aerial vehicles

and are included in mini turbojet systems, can be manufactured precisely with

5 axis CNC machines.

We produce mixer throat segments produced with 3-axis profile processing method with surface sensitivity developed for the gypsum sector. For resistance against abrasion; Special surface coatings such as Tungsten-Carbide, Titanium coating are realized and long life is provided.

With our multi-axis machining capability, we are able to reveal complex surface structures.

Special winding devices for insulation and insulation materials in the energy sector are manufactured with high precision.

Manufacturing of special hydraulic and pneumatic equipments is carried out by providing dimensional and positional tolerance.

Aviation Sector parts can be manufactured with high quality equipments.

With our Mazak J200 Integrex CNC machine, we manufacture hydraulic pistons and shafts with complex geometry.

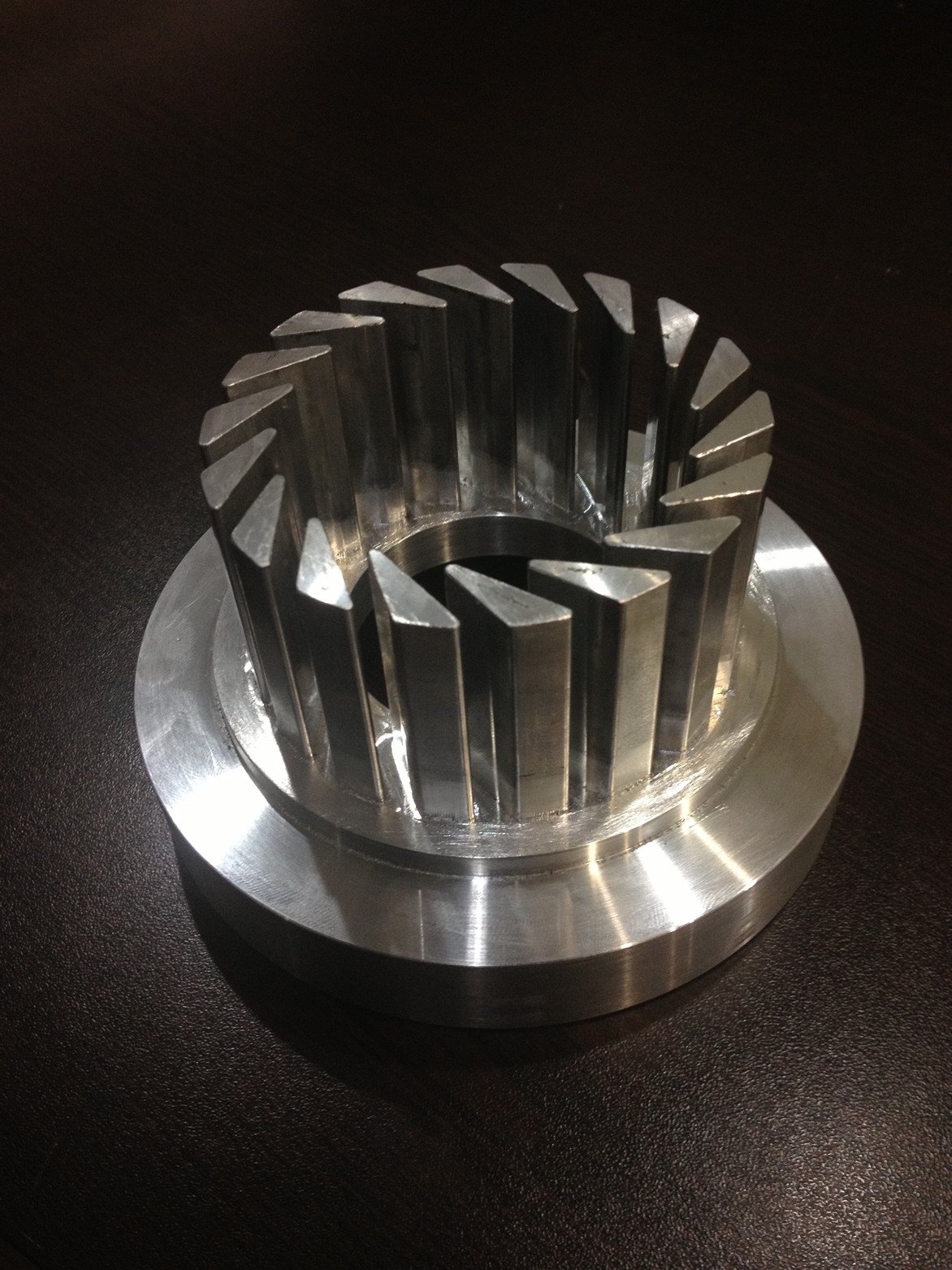

We are able to precisely produce rotor-stator heads for many mixing processes, especially inline mixers.

We manufacture special parts of body, rotor-stator, magnetic plates for Electric Motors.